Enhancing the human experience through innovative, museum display cases engineered with precision, manufactured to world-class quality, for the first time, right here in the USA.

Case Study 1

US Naval Academy Museum

The Naval Academy project consisted of two galleries. The ship model gallery on the second floor…

Case Study 2

Pearl Harbor Visitor Center and Museum

The cases at Pearl Harbor Visitor Center had stringent requirements. All case environments were controlled…

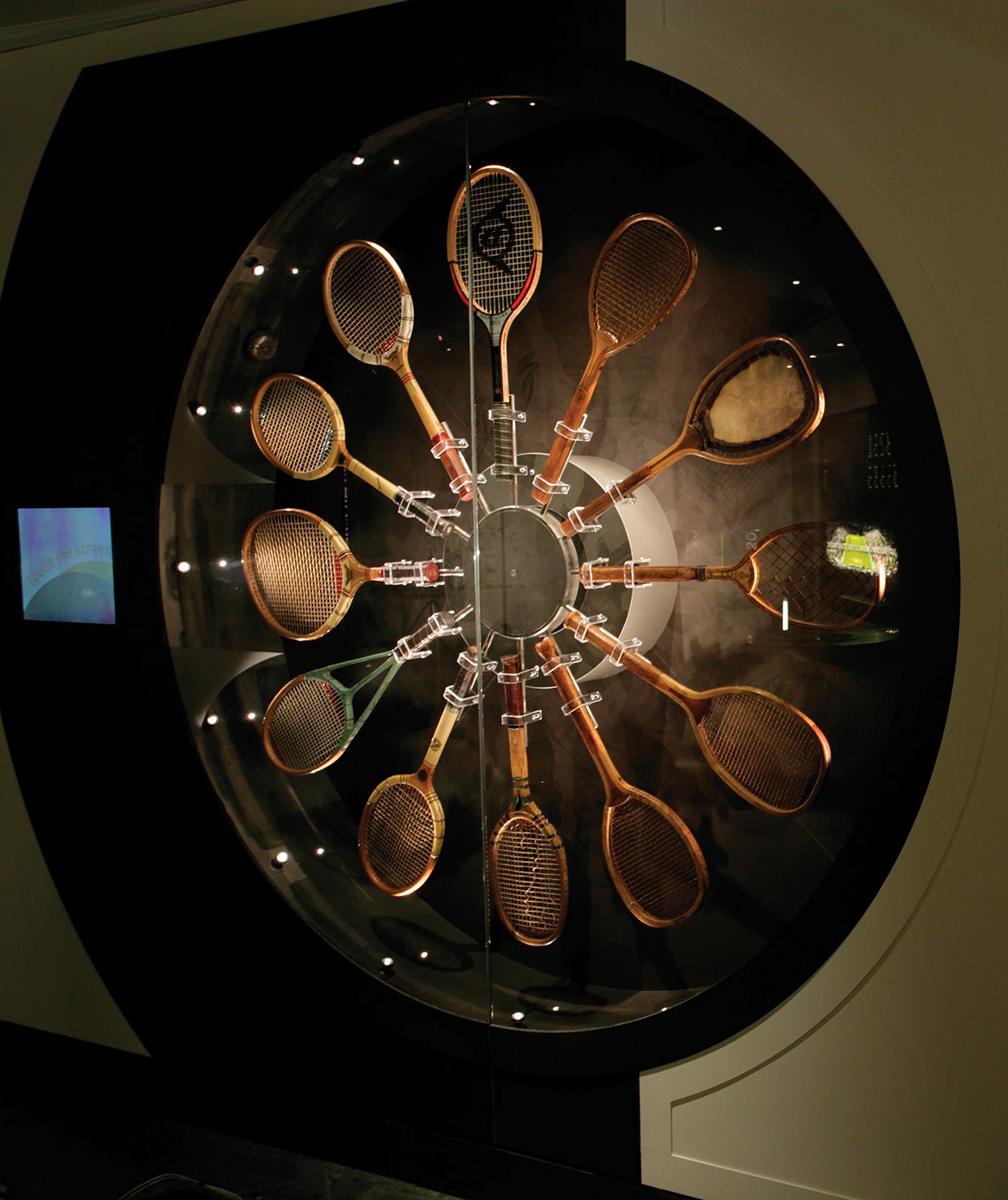

Case Study 3

White House Visitor Center

Majority of the cases at this high-profile visitor center were custom except a couple NOVA fascia-hinged cases…

Overview

At CAISAS, we understand that design and development of conservation-grade cases is a collaborative process. Hence, we adopt a Listen-Question-Collaborate-Resolve approach to all of our display case manufacturing projects. We sincerely believe that our full grasp of every stage of a project, as well as our rigorous quality control, is fundamental to success. We are committed to constant research and development of our products to the market’s ever-changing needs through innovation and continuous improvement.

While we strongly encourage all of our clients and exhibit designers to consult with us as early as feasible, we are always ready to assist your display case needs at any time. Our team of experienced professionals are happy to collaborate with you on determining choice of material, climate control needs, lighting, accessibility, logistics and more.

As an independent display case manufacturing company, we’re able to offer top-quality materials, localized support, and timely installations compared to our international competitors-to provide the best cost to value ratio while saving valuable time. Our team of engineers, technicians and craftsman experts, paired with the industry’s best equipment, processes, tools and materials are committed to providing you with world-class museum display cases.

At CAISAS, we have a customized and comprehensive approach to provide the best possible product ensuring that our cases display, preserve, and secure your precious timeless and priceless artifacts and objects.

Who We Are

CAISAS (pronounced “cases”) is an independent entity (LLC) using Color-Ad, Inc. existing resources and world-class components to meet mission-critical museum and visitor center display case manufacturing requirements in the U.S.

What’s in a name?

The name CAISAS, pronounced “cases” is a unique name reflecting our distinct capabilities, that uses part of the Color-Ad and Armour Systems initials: CA (Color-Ad) IS (is) AS (Armour Systems).

With decades of experience, plus cutting-edge artistry and innovation, we’re able to provide the highest quality exhibits and displays for every client. We’re proud to take part in every step of the display process—from project management and CAD engineering to graphic design and custom woodworking. Our team is experienced and versatile, providing you with a customized approach for every project.

For over 60 years, we’ve taken on a wide range of projects for clients including The National Park Service, The US Naval Academy, and countless museums and universities. Now, using the best quality OEM materials, and industry insight from display manufacturing leader, Armour Systems, we’re equipped to supply America’s parks, universities, and historical organizations with the most customized and comprehensive exhibits and displays right here in the U.S..

Our Vision

To be the North American Museum Display Case Manufacturer of Choice for Conservation Grade Cases

“What impressed me the most was the ability of Don Grogan and the team to anticipate problems, plan for them, and more importantly, calmly trouble shoot unanticipated difficulties and creatively resolve them as they occurred.”

“The favorable reaction of the 250 Pearl Harbor survivors and their families who were on hand for the dedication on December 7, 2010 attest to the success of their effort.”

– Michael Paskowsky, Project Manager

Pearl Harbor Visitor Center – World War II Valor in the Pacific, Hawaii

“There are many exhibit fabrication companies from which to choose, but I know that the CAISAS team offers not only competitive pricing, but stands behind their product. In both of these projects,they proved to be a superior company with which to work. Not only are they exceedingly competent in their fabrication skills, they are also a great company in their personal relations; never demanding, always professional, and always cooperative. They take pride in their work, and it shows.”

– Dr. J Scott Harmon, Director – USNA Museum

United States Naval Academy – Preble Hall Exhibits, MD

At CAISAS, we believe in constantly updating our technology, equipment and production processes, using our state of the art CNC machines for sheet cutting, profile cutting, milling and various other engineering operations to deliver consistent quality and precision.

MUSEUM DISPLAY & EXHIBIT LIGHTING SYSTEMS

With the rapid development of display and exhibit lighting technology, there has been a move to create gallery and museum spaces that are brighter, capturing daylight where possible, while employing non-reflective glass and light fittings that are so small and well concealed that they are not always visible to the naked eye.

You can specify museum exhibit lighting systems within cases according to color, energy efficiency, or the sensitivity of the object. You have a range of showcase display lighting solutions and designs available, utilizing the latest in fiber-optic and LED technologies.

Images of various projects depicting multiple styles of cases and lighting systems can be viewed by visiting our gallery under Our Work.

Rob Velke

President

Organizational Leadership – Business Operation – Policy Formulation

INDUSTRY EXPERIENCE: 33 Years

Mechanically inclined- Design Savvy- Customer Centric- Versatile skill set- Trained in the UK and also possess hands on experience on the complete range of cases we offer.

[email protected]

D: 703.508.0052

O: 703.631.9100

Mike Bures

Vice President

Senior Management Team – Assists in Business Operations – Cost Engineering- Policy INDUSTRY EXPERIENCE: 40 Years Field Operations, Manufacturing – On Site Project Leadership – Engineering and Estimation Support- Problem Solving Business Operations Mechanically inclined – Customer-Centric – Versatile skill set – Trained in the UK and also possesses hands-on experience on the complete range of cases we offer.

S.K. Rao

Sr. Vice President

Business Development / Strategy

Organizational Leadership – Cost Engineering, Strategic Resourcing, Project Direction, Total Quality Management, Project Leadership – Customer Service.

INDUSTRY EXPERIENCE: 32 Years

Strategically inclined, high degree of techno commercial sense – customer advocacy, possess versatile skill set – conversant with the complete range of cases we offer to provide tailored solutions to the individual needs of high-profile clients.

[email protected]

D: 516.250.9661

O: 703.631.9100

Julie Velke

CFO

Organizational Finance & Administration Leadership – Business Operations – Policy Making, Systems Development Human Resources – Licensing/ Certifications INDUSTRY EXPERIENCE: 29 Years Organizational Leadership, Accounting/ Finance, Taxes, Auditing, Labor Laws, Human Resources, Customer Service – Strategic Communication, Contract Administration. She was an integral part of striking the licensing agreement which helped CAISAS to be launched.

Don Grogan

Vice President (Technical Solutions)

Engineering – Design for Manufacture Solution, Problem Solving

INDUSTRY EXPERIENCE: 41 Years

Value Analysis-Cost Engineering, Project Direction, Field Operations

Mechanically inclined – Customer Centric- Versatile Skill set- Integral part of ArmourSystems Technology Transfer – Trained On job in the UK and on several NPS projects and hold expertise in the complete range of cases we offer.

Jonathan Scott

Shop Floor Manager

Lead day-to-day Manufacturing Operations of Display Case Manufacture INDUSTRY EXPERIENCE: 33 Years Production Planning and Control, Quality Assurance, Scheduling – CAD Engineering and Project Coordination Mechanically Inclined – Fabrication Savvy – Customer Centric – Versatile skill set pertaining to manufacturing techniques – well versed the complete range of cases we offer.

Mike Gagin

CAD Design Specialist

Design for Manufacture (DFM) Mechanically inclined – Design Savvy – Customer Centric – Trained in the UK and on jobs here about the complete range of cases we offer.Why CAISAS?

& What American-built cases offer?

- Time savings (no overseas shipping- no customs)

- Best cost-to-value ratio

- Precision engineered – high-quality – conservation grade cases

- Experienced and customer centric team right here, in the USA for the North American market.